Membrane roofs are extremely durable and reliable, but when they leak, it’s often because of something that weighs just a few grams, like a simple sheet metal screw.

In our experience, HVAC service often precedes a leak. That’s because servicing a rooftop HVAC unit requires removing a door to get inside of the unit. The door is held in place by sharp sheet metal screws. HVAC technicians will often drop the old corroded screws and leave them on the roof, reinstalling the door with new screws. As soon as someone steps on those screws, they can create leaks.

The good news is that prevention can come in two forms. One is obvious—watch who goes on your roof, and ensure they are leaving no debris. Back that up by regularly inspecting the roof for screws, branches, acorns or other possible hazards.

The other form of prevention is to choose the strongest membrane possible. Nothing is impervious, but stronger is better. Leaks caused by this type of damage are not covered under warranties, so it pays to invest in the best possible membrane.

Strong Reinforcement

Modified bitumen roofs can be 180mils thick and have a tough granulated surface, but they are no match for screws. Step on the screw on a hot day and the screw’s sharp point will likely punch right through, causing a leak. By comparison, FiberTite has superior fabric, not thickness, that can prevent these common punctures.

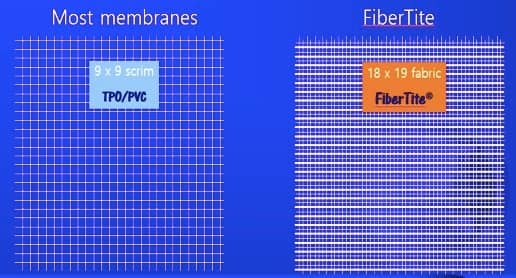

Single ply membranes and modified bitumens incorporate either fiberglass or polyester reinforcing to give strength to their product. The most common style used in a single ply is a “9 x 9” polyester scrim. This is similar to a screen door, leaving small areas that are not reinforced at all, making them quite vulnerable to puncture.

Example of the reinforcements used in roofing membranes

The reason a “9x9” scrim is used in the first place is because an open scrim is needed to produce a laminated product. Although lamination is the most cost-effective to make a roofing membrane, it leaves the building owner vulnerable to small punctures. Also, laminated products can allow water to wick into the membrane once the membrane is cut or when the caulk fails on a cut edge. Once water enters the membrane, it begins to degrade.

Laminated membrane with open scrim reinforcement

Long-term Savings

Finding the best roof system for your building means weighing a number of factors, not just looking at how long the warranty lasts. Things that seem insignificant, like reinforcement, can play a major role in keeping your roof protected over the next 20 years. These little things really matter, because a sheet metal screw isn’t little at all when it comes to a membrane roof. See how FiberTite and its superior reinforcement will free you from thinking about these tiny details… because we already did.

What methods do you use to prevent leaks? Tell us about them in the comments!

-1.png?width=500&height=271&name=FiberTite_Only%20(500px%20wide)-1.png)

-1.png)