In marketing, there are words we often see and gloss over because over time they lose their meaning. Words that come to mind are innovative, advanced and next generation. At FiberTite, we often use the words proven, trusted and high performance.

The point is that words are worth nothing without the proof to back them up. In a recent blog, “The Thickness Paradigm: How the Roofing Membrane Industry Got It Backwards,” I detailed how with most technologies, such as phones and computers, thinner is better. And the same holds true when it comes to roof membranes where there are thinner, stronger and better engineered products. I discussed why this is true and how the base fabric, ELVALOY™ Ketone Ethylene Ester content and overall construction of the membrane contribute to a low-maintenance, high-performance roof system.

For this blog, I am going to dig a little deeper into the origin of ELVALOY™ KEE membranes and how they compare with other commonly used roofing membrane materials.

Which would you trust?

If you are reading this, you are likely a roofing consultant, architect or building owner with a stake in how a roof system will perform over time. You know that a leaky roof can cause years of headaches and costly repairs, wasting valuable time and resources or hurting your reputation. We can all agree that the best kind of roof membrane requires little to no attention during its long lifetime.

If you are reading this, you are likely a roofing consultant, architect or building owner with a stake in how a roof system will perform over time. You know that a leaky roof can cause years of headaches and costly repairs, wasting valuable time and resources or hurting your reputation. We can all agree that the best kind of roof membrane requires little to no attention during its long lifetime.

I talked a little bit in my last blog about the FiberTite origin story. It is born from technology created by the Seaman Corporation. That geomembrane technology has been used for decades in applications where leaks are not an option, including bioremediation, wastewater impoundments, landfills, leachate ponds, oil booms and more. These industrial coated fabric products are trusted in some of the world’s harshest environments because of their proprietary knitting and weaving designs and proprietary compounding and coating formulas.

Now ask yourself this: Would I trust that 80-mil TPO roof membrane to hold up in these applications? Would I trust it to protect communities and the environment?

>>>If the answer is no, why would you trust it on your roof?

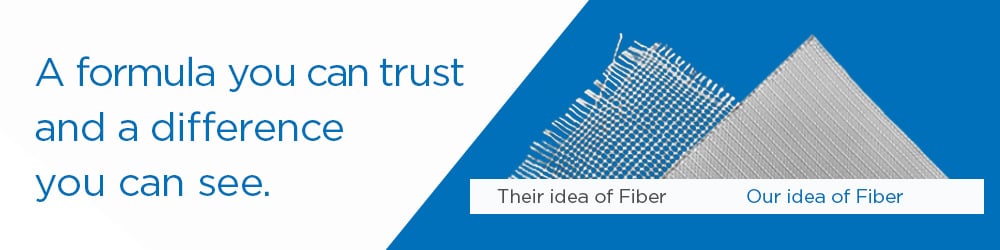

The single-ply roof membrane of a FiberTite roof systems is based on the same technologies and composition that are proven and are trusted to prevent punctures and subsequent leaks in these demanding applications. Again, it all comes down to the base fabric and the formula, which includes the optimal ratio of ELVALOY™ Ketone Ethylene Ester content in roof membranes.

ELVALOY™ KEE vs. PVC and ELVALOY™ KEE vs. “KEE”

PVC, or vinyl, is one of the most used materials in the world. It is found in building materials, telecommunications, product packaging, health care—and so much more. Its properties make it ideal for a nearly endless list of applications.

When it came to PVC and roof membranes, the challenge has been that PVC is rigid in its natural state. To this day, liquid plasticizers are commonly used to provide more flexibility in traditional PVC roof membranes; however, when exposed to heat and chemicals, the plasticizer migrates out. This process causes the vinyl to shrink, become brittle and fail.

Ultimately, FiberTite’s solution was to use a solid plasticizer (the aforementioned ELVALOY™ KEE) as an alternative to liquid plasticizers and that proved to be a game changer for the industry. When compared to traditional PVC membranes, FiberTite’s ELVALOY™ KEE plasticizer will not migrate out and forms a new alloy with PVC with a higher molecular weight. In labs and in the field for more than 40 years, FiberTite’s formula and level of ELVALOY™ KEE content has been proven to:

Ultimately, FiberTite’s solution was to use a solid plasticizer (the aforementioned ELVALOY™ KEE) as an alternative to liquid plasticizers and that proved to be a game changer for the industry. When compared to traditional PVC membranes, FiberTite’s ELVALOY™ KEE plasticizer will not migrate out and forms a new alloy with PVC with a higher molecular weight. In labs and in the field for more than 40 years, FiberTite’s formula and level of ELVALOY™ KEE content has been proven to:

- Maintain flexibility over long-term exposure to water and temperature fluctuation.

- Increase toughness and abrasion resistance.

- Resist harsh chemicals and industrial pollutants, including jet fuel, vegetable oils, animal fat, ethylene glycols, and acids and bases.

But take note: Just because a roof membrane contains some level of ELVALOY™ KEE, doesn’t mean it is a true ELVALOY™ KEE membrane. To put it simply, to get the best performance, you want ELVALOY™ KEE with PVC, not PVC with some ELVALOY™ KEE.

In fact, the level of ELVALOY™ KEE content matters so much when it comes to performance that there is a standard that specifically addresses the level of ELVALOY™ KEE content in a roof membrane. The ASTM D6754-02 Standard Specification for ELVALOY™ KEE-Based Sheet Roofing dictates that properly compounded KEE coatings that utilize a minimum 50% KEE terpolymer content and are applied to high-quality base fabrics can exceed the design service life expectations at 70% of the thickness required of conventional “PVC” roofing membranes.

Despite other “KEE membranes” on the market, FiberTite is still the only one that meets the ASTM standard for ELVALOY™ KEE content. So just because a product contains some ELVALOY™ KEE, doesn’t mean that you can expect the same level of performance that you can from FiberTite.

More than words

Yes, we use the words proven, trusted and higher performing often to describe FiberTite products. But we use them because they are the best way to describe the value we bring to commercial buildings and those who build and maintain them.

These words have deep meaning when we use them because they are based on data and more than four decades of real-world testing as both geomembranes in harsh, critical environments and as part of roof systems that have lasted 25-plus years.

>>>>>For more data and proof points on FiberTite vs. competitive products, explore the following downloads:

- Competitive performance testing infographic

- FiberTite vs. PVC white paper

- FiberTite vs. TPO white paper

- FiberTite vs. Modified Bitumen white paper

ELVALOY™ is a trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow.

-1.png?width=500&height=271&name=FiberTite_Only%20(500px%20wide)-1.png)

-1.png)